Cast iron sprockets are essential components in various industrial and mechanical applications, known for their durability, strength, and cost-effectiveness. These sprockets are widely used in conveyor systems, agricultural machinery, and heavy-duty equipment where reliability is paramount. Made from high-quality cast iron, they offer excellent wear resistance and can withstand harsh operating conditions. In this comprehensive guide, we delve into the specifics of cast iron sprockets, covering their parameters, benefits, and common questions to help you make an informed decision for your needs.

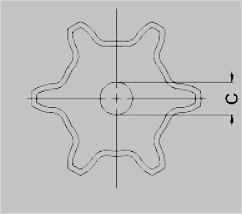

Understanding the technical specifications of cast iron sprockets is crucial for selecting the right product. Below is a detailed list of parameters that define their performance and suitability for different applications.

For a quick comparison, refer to the table below summarizing standard cast iron sprocket models and their attributes.

| Model Number | Teeth Count | Pitch (inches) | Bore Size (inches) | Hub Type | Weight (lbs) | Application |

|---|---|---|---|---|---|---|

| CI-SP-1020 | 10 | 0.5 | 0.75 | Plain | 2.5 | Light-duty conveyors |

| CI-SP-2540 | 25 | 0.75 | 1.5 | Hubbed | 8.0 | Agricultural machinery |

| CI-SP-4060 | 40 | 1.0 | 2.0 | Double-hub | 15.0 | Industrial drives |

| CI-SP-60100 | 60 | 1.25 | 3.0 | Hubbed | 25.0 | Heavy-duty equipment |

| CI-SP-80120 | 80 | 1.5 | 4.0 | Double-hub | 40.0 | Mining operations |

Cast iron sprockets offer numerous benefits that make them a preferred choice in many industries. Their high tensile strength and ability to absorb vibrations reduce noise and wear on chains. The cost-effectiveness compared to steel sprockets allows for budget-friendly solutions without compromising performance. Additionally, their machinability enables easy customization for specific applications, while the inherent lubrication properties of cast iron minimize maintenance requirements. These sprockets are also recyclable, aligning with environmental sustainability goals.

What are the main applications of cast iron sprockets?

Cast iron sprockets are commonly used in conveyor systems, farming equipment, construction machinery, and industrial drives where durability and cost efficiency are key. They excel in environments with moderate loads and speeds.

How do I choose the right teeth count for my application?

Select the teeth count based on the desired speed ratio and torque. Higher teeth counts provide smoother operation and reduced wear for high-speed applications, while lower counts offer more torque for heavy loads. Consult the machinery specifications or a professional for precise selection.

Are cast iron sprockets suitable for outdoor use?

Yes, but they require protective coatings like zinc plating or paint to prevent rust and corrosion in outdoor or humid conditions. Regular maintenance, such as cleaning and lubrication, can extend their lifespan in such environments.

What maintenance is needed for cast iron sprockets?

Routine inspections for wear, proper lubrication of the chain, and checking for alignment issues are essential. Replace sprockets if teeth become hooked or worn beyond manufacturer recommendations to avoid chain slippage or failure.

Can cast iron sprockets be used with any type of chain?

They are designed to work with standard roller chains; ensure the chain pitch matches the sprocket pitch. Using mismatched chains can lead to premature wear, noise, and potential system failure.

How does cast iron compare to steel in sprockets?

Cast iron is more economical and offers good wear resistance and vibration damping, but it is less strong than steel. Steel sprockets are better for high-load, high-speed applications, while cast iron is ideal for moderate conditions where cost is a factor.

What is the typical lifespan of a cast iron sprocket?

Lifespan varies based on usage, load, and maintenance. Under normal conditions with proper care, they can last several years. Factors like excessive load, poor lubrication, or misalignment can reduce this duration.

Are custom sizes available for cast iron sprockets?

Yes, many manufacturers offer customization for bore size, teeth count, and hub design to meet specific requirements. Provide detailed specifications for accurate machining and optimal performance.

Do cast iron sprockets require special installation tools?

Basic tools like wrenches, presses, or arbors are sufficient for installation. Ensure the shaft is clean and properly aligned to avoid damage. Follow manufacturer guidelines for torque settings and securing methods.

How can I identify when a cast iron sprocket needs replacement?

Look for signs such as worn or bent teeth, cracking, or excessive play on the shaft. Regular monitoring and measuring tooth wear against industry standards can help determine replacement timing.