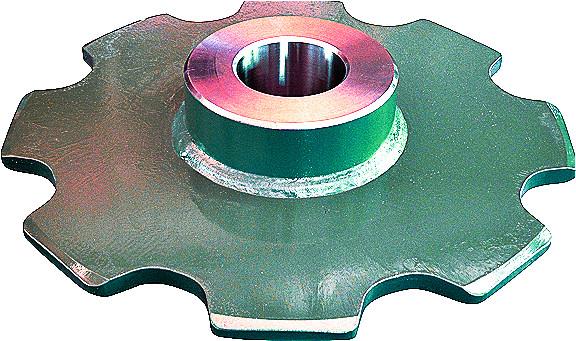

A sprocket is a toothed wheel designed to engage with a chain or track. It is a critical component in various mechanical systems, including bicycles, motorcycles, industrial machinery, and automotive applications. Sprockets facilitate the transfer of rotary motion between shafts where gears are unsuitable, offering efficient power transmission with minimal slippage. They come in diverse sizes, materials, and tooth configurations to meet specific operational demands, ensuring durability and performance under varying loads and environmental conditions.

| Parameter | Description | Range/Availability |

|---|---|---|

| Bore Diameter | Inner hole size for shaft mounting | 10 mm to 100 mm |

| Number of Teeth | Total teeth on the sprocket | 10 to 60 teeth |

| Pitch | Distance between tooth centers | 0.25 inches to 2.5 inches |

| Material | Construction material | Steel, Stainless Steel, Aluminum |

| Load Capacity | Maximum operational load | Up to 5000 N |

| Temperature Range | Operational limits | -40°C to 200°C |

Choosing the right sprocket involves evaluating several factors:

Q: How do I determine the correct sprocket size for my system?

A: Measure the chain pitch (distance between pin centers) and count the teeth on your current sprocket. Refer to manufacturer charts for compatibility, or consult engineering specifications based on torque and speed requirements.

Q: What maintenance do sprockets require?

A: Regularly inspect for wear, misalignment, and lubrication. Clean debris and apply chain-compatible lubricant to reduce friction. Replace sprockets if teeth become hooked or visibly worn to prevent chain damage.

Q: Can I use a sprocket with a different chain brand?

A: Yes, if the pitch and tooth profile match. However, for optimal performance and longevity, use sprockets and chains from the same manufacturer or certified compatible products.

Q: What causes sprocket wear, and how can it be minimized?

A: Wear results from friction, misalignment, overload, or poor lubrication. Minimize it by ensuring proper alignment, using high-quality materials, maintaining adequate lubrication, and avoiding excessive loads.

Q: Are there lightweight sprockets for high-speed applications?

A: Yes, aluminum sprockets are ideal for high-speed scenarios due to their reduced mass, which lowers inertia. They are commonly used in robotics, aerospace, and racing industries.

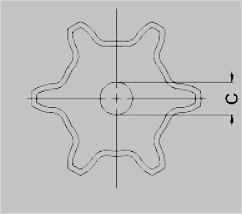

Q: How do I install a sprocket correctly?

A: Secure the sprocket onto the shaft using appropriate keys and fasteners. Ensure it is perpendicular to the shaft and aligned with other sprockets in the system. Tighten to the recommended torque specification to avoid slippage.