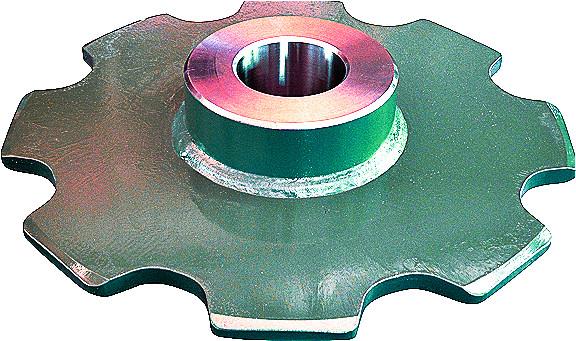

Conveyor sprockets are specialized wheels with teeth designed to engage with the links of a conveyor chain, facilitating the smooth and efficient transfer of mechanical motion in conveyor systems. They play a critical role in industries such as manufacturing, logistics, and material handling by ensuring reliable power transmission and movement of goods along production lines. These components are engineered to withstand high loads, resist wear, and operate in various environmental conditions, making them indispensable for maintaining operational continuity.

Understanding the technical specifications of conveyor sprockets is essential for selecting the right component for your system. Below is a detailed breakdown of key parameters, presented in a list and table format for clarity.

| Parameter | Description | Common Values/Ranges | Importance |

|---|---|---|---|

| Pitch Diameter | Diameter of the circle through the chain pin centers | 50 mm to 500 mm | Determines compatibility with chain pitch |

| Number of Teeth | Total teeth on the sprocket | 10 to 60 teeth | Affects speed ratio and smoothness of operation |

| Bore Size | Inner diameter for shaft mounting | 20 mm to 100 mm | Ensures proper fit and reduces vibration |

| Material | Construction material | Steel, Stainless Steel, Nylon | Impacts strength, weight, and corrosion resistance |

| Hardness (HRC) | Surface hardness measurement | 40 HRC to 60 HRC | Enhances wear resistance and lifespan |

| Hub Type | Design of the central hub | Plain, Finished Bore, Pilot Bore | Influences ease of installation and maintenance |

| Weight | Mass of the sprocket | 0.5 kg to 15 kg | Affects system inertia and energy efficiency |

| Temperature Range | Operational temperature limits | -20°C to 150°C | Ensures performance in varying environments |

Conveyor sprockets are utilized across diverse industries to enable efficient material handling. In manufacturing plants, they drive assembly line conveyors, transporting components between workstations. Logistics and warehousing sectors rely on them for sorting and moving packages in automated systems. Food processing industries use stainless steel sprockets to meet hygiene standards, while mining and heavy machinery applications demand high-strength sprockets for abrasive environments. Their versatility ensures seamless operation in both light-duty and heavy-duty scenarios, contributing to increased productivity and reduced downtime.

What factors should I consider when selecting a conveyor sprocket?

Consider the chain type and pitch, number of teeth for desired speed ratio, bore size for shaft compatibility, material based on environmental conditions (e.g., corrosion resistance), and load capacity to ensure durability under operational stresses.

How often should conveyor sprockets be inspected and replaced?

Inspect sprockets every 3-6 months for signs of wear, such as tooth deformation or cracking. Replacement frequency depends on usage intensity; typically, high-load systems may require replacement every 1-2 years, while lighter systems can last 3-5 years.

Can conveyor sprockets be customized for specific applications?

Yes, sprockets can be customized in terms of material, tooth profile, bore size, and hub design to meet unique requirements, such as extreme temperatures, high corrosion environments, or specialized mounting needs.

What are the common causes of conveyor sprocket failure?

Common causes include improper alignment leading to uneven wear, overloading beyond rated capacity, inadequate lubrication causing friction and heat buildup, and material fatigue from continuous operation without maintenance.

How do I ensure proper installation of a conveyor sprocket?

Ensure the shaft is clean and free of debris, align the sprocket accurately with the chain and other components, use appropriate fasteners (e.g., set screws or keys), and follow torque specifications to avoid loosening during operation.

What is the difference between roller chain sprockets and conveyor sprockets?

Roller chain sprockets are designed for power transmission in drive systems, often with higher precision, while conveyor sprockets are optimized for engaging with conveyor chains to move materials, focusing on durability and load distribution in continuous operation.

Are there maintenance tips to extend the life of conveyor sprockets?

Regularly lubricate the chain and sprocket interface to reduce wear, check for misalignment and correct it promptly, avoid over-tensioning the chain, and conduct routine inspections to identify issues early, such as tooth wear or corrosion.