Everything You Need to Know About Industrial Sprockets

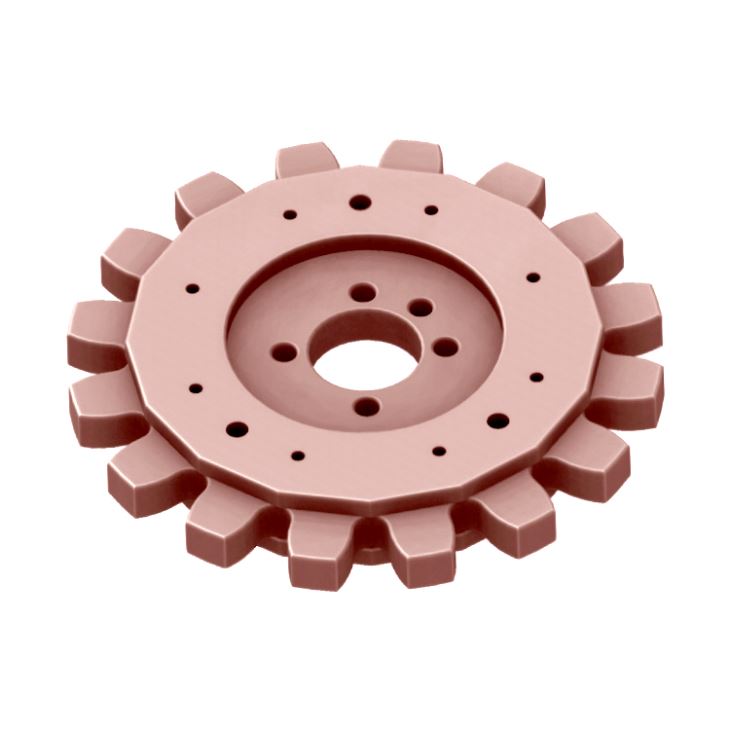

Industrial sprockets are critical components in machinery and conveyor systems, designed to transmit rotary motion between two shafts where gears are unsuitable. They are typically used with chains or belts to ensure efficient power transmission in various industrial applications. High-quality industrial sprockets enhance durability, reduce maintenance costs, and improve operational efficiency in sectors such as manufacturing, agriculture, mining, and automotive.

Key Parameters of Industrial Sprockets

Understanding the specifications of industrial sprockets is essential for selecting the right product for your needs. Below are the primary parameters detailed in a list format for clarity:

- Pitch Diameter: The diameter of the pitch circle, which determines the chain engagement and smooth operation.

- Number of Teeth: Affects the speed ratio and torque; common ranges are from 10 to 120 teeth.

- Bore Size: The inner diameter that fits onto the shaft, customizable based on shaft dimensions.

- Material: Typically made from steel, stainless steel, cast iron, or plastic, depending on application requirements.

- Hardness: Measured on the Rockwell scale (e.g., HRC 50-60 for steel sprockets) to resist wear and deformation.

- Width: The thickness of the sprocket, influencing chain compatibility and load capacity.

- Type: Includes chain sprockets, belt sprockets, idler sprockets, and double-pitch sprockets for specific uses.

Detailed Specifications Table

For a comprehensive overview, refer to the table below summarizing standard industrial sprocket specifications:

| Parameter | Description | Common Values |

|---|---|---|

| Pitch | Distance between chain pins | 0.25 inch to 2.5 inches |

| Teeth Count | Number of teeth on the sprocket | 10 to 120 |

| Bore Diameter | Inner hole size for shaft fitting | 0.5 inch to 6 inches |

| Material Grade | Type of material used | Steel (AISI 1045), Stainless Steel (316), Cast Iron |

| Load Capacity | Maximum weight or force supported | Up to 5000 kg depending on size and material |

| Temperature Range | Operating temperature limits | -40°C to 150°C for standard models |

Industrial Sprocket FAQ

Here are some frequently asked questions about industrial sprockets to address common concerns:

What is an industrial sprocket used for?

An industrial sprocket is used to transmit mechanical power between rotating shafts, often in conjunction with a chain or belt, in machinery like conveyors, engines, and agricultural equipment.

How do I choose the right sprocket size?

Select the sprocket based on pitch diameter, number of teeth, bore size, and material compatibility with your system's chain and load requirements. Consult engineering specifications or a professional for accurate sizing.

What materials are best for corrosive environments?

Stainless steel or coated steel sprockets are ideal for corrosive environments due to their resistance to rust and degradation, ensuring longer lifespan and reliability.

How often should industrial sprockets be maintained?

Regular maintenance, including lubrication and inspection for wear, should be performed every 3 to 6 months, depending on usage intensity and operating conditions.

Can sprockets be customized for specific applications?

Yes, sprockets can be custom-made with specific teeth profiles, bore sizes, and materials to meet unique industrial needs, such as high-temperature or heavy-duty applications.

What are the signs of a worn-out sprocket?

Common signs include uneven tooth wear, chain slippage, increased noise, and reduced efficiency. Replace sprockets promptly to avoid machinery damage.

Industrial sprockets play a vital role in ensuring smooth and efficient operations across various industries. By understanding their parameters and maintenance needs, you can optimize performance and extend equipment life. Always source from reputable manufacturers to guarantee quality and reliability.