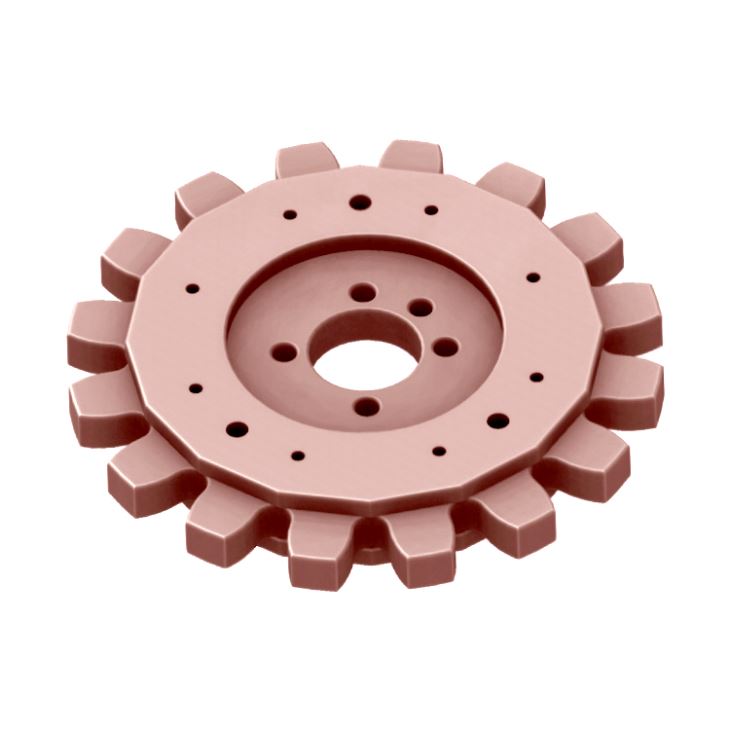

Agricultural sprockets are crucial components in farming machinery, designed to transmit rotary motion between shafts via chains. They are integral to equipment like tractors, combines, and planters, ensuring efficient power transfer in various agricultural applications. Made from durable materials, these sprockets withstand harsh environments, including exposure to dirt, moisture, and heavy loads, making them essential for reliable farm operations.

Our agricultural sprockets are engineered with precision to meet high standards. Below are the detailed parameters presented in lists and a table for clarity.

| Parameter | Specification Range | Application |

|---|---|---|

| Teeth Number | 10 - 60 | Adjusts speed and torque for different machinery |

| Bore Size (inches) | 0.5 - 3.0 | Fits various shaft diameters in farm equipment |

| Pitch (inches) | 0.375, 0.5, 0.625 | Compatible with standard roller chains |

| Material Grade | Grade 1045 Steel, Alloy Steel | Provides high tensile strength and wear resistance |

| Weight (lbs) | 0.5 - 15 | Varies based on size and material density |

Our sprockets offer numerous advantages for farming operations. They ensure smooth power transmission, reduce downtime due to their robust construction, and are designed for easy maintenance. With precise engineering, they minimize chain slippage and wear, leading to longer equipment life and lower operational costs. Additionally, their corrosion-resistant coatings make them ideal for outdoor and abrasive environments common in agriculture.

What types of chains are compatible with agricultural sprockets?

Agricultural sprockets are typically designed to work with roller chains that meet ANSI standards. Common chain sizes include #35, #40, #50, and #60, depending on the sprocket pitch and teeth configuration. It's essential to match the chain and sprocket specifications to ensure optimal performance and avoid premature wear.

How often should agricultural sprockets be inspected and replaced?

Regular inspection is recommended every 250-500 hours of operation or at least once per farming season. Look for signs of wear such as hooked teeth, cracks, or excessive play. Replacement should occur when wear exceeds 5% of the original tooth profile to prevent chain failure and machinery damage.

Can agricultural sprockets be customized for specific machinery?

Yes, we offer customization options for bore size, teeth count, and material based on your equipment requirements. Provide details such as shaft diameter, chain type, and operating conditions, and we can manufacture sprockets tailored to your needs for enhanced compatibility and efficiency.

What maintenance practices extend the life of agricultural sprockets?

Proper maintenance includes regular cleaning to remove debris, lubrication of the chain and sprocket interface, and ensuring correct alignment and tension. Avoid over-tightening chains, as this can cause undue stress. Storing equipment in dry conditions when not in use also helps prevent rust and corrosion.

Are there environmental considerations for agricultural sprockets?

Our sprockets are designed with eco-friendly practices, using recyclable materials and coatings that minimize environmental impact. However, always dispose of worn sprockets responsibly by recycling metal components to reduce waste and support sustainability in farming operations.