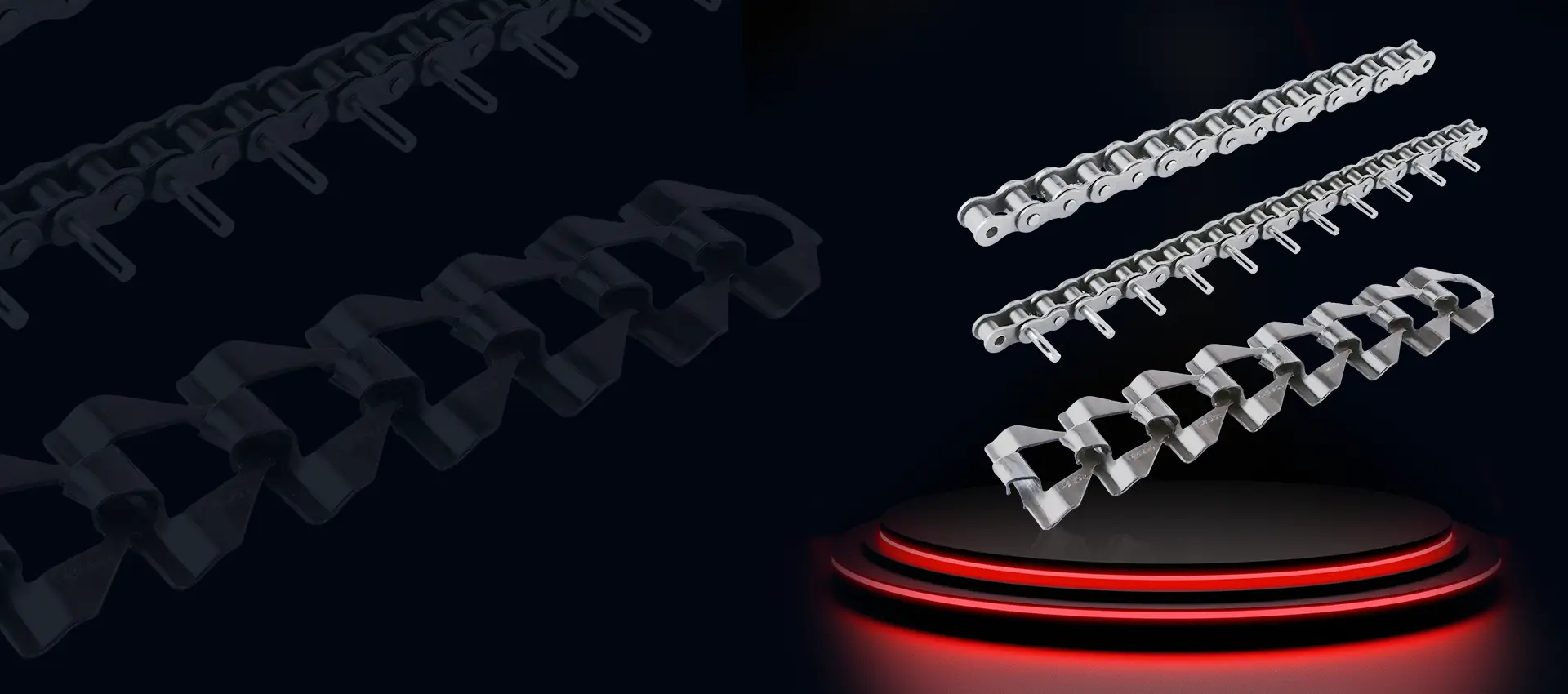

Manufacturing And supplying of Industrial Conveyor Chains & Sprockets.

Manufacturing And supplying of Industrial Conveyor Chains & Sprockets.

ISO9001-2015, ISO14001-2015, and ISO45001-2018.

Raydafon Technology Group Co.,Limited focuses on the design and manufacturing of high-precision cold heading chain rollers, sleeves, and various types of chains. The enterprise has passed three major management system certifications: ISO9001-2015, ISO14001-2015, and ISO45001-2018. The company's leading products include: engineering chain, cement chain, sugar machine chain, palm oil chain, steel sales chain, garbage incinerator chain, stainless steel conveyor flat top chain, and various types of chain cold roller and sleeve accessories······